Background (2019 - Present)

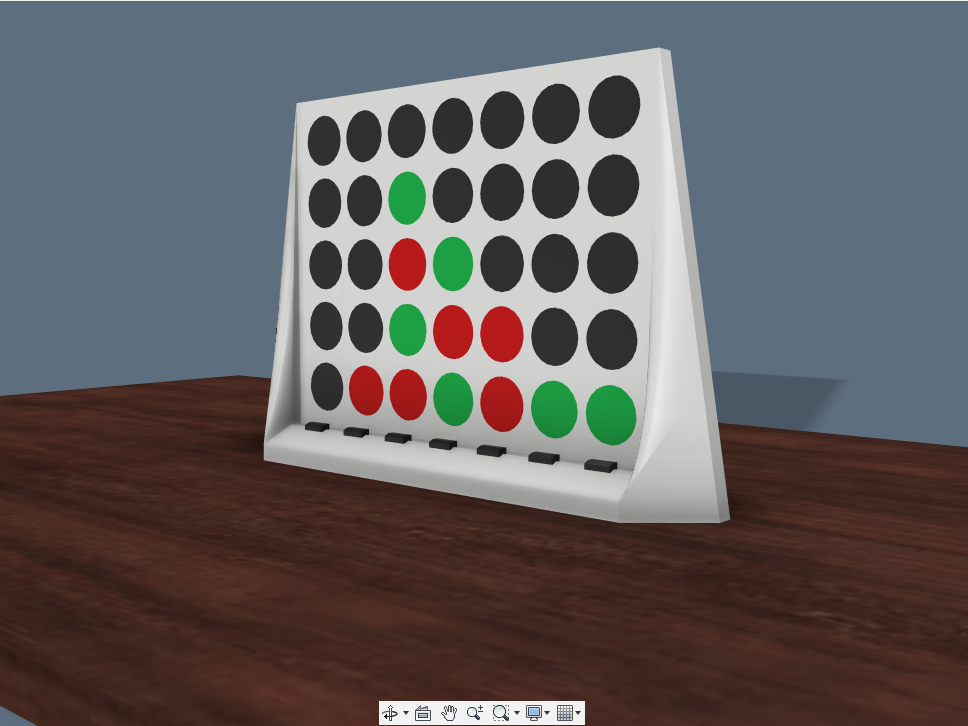

This case study details the project lifecycle of a personal endeavor I have dubbed Panel Shifter.

I viewed the production of Panel Shifter as an exercise in design and creation. This undertaking forced me to familiarize myself with the fundamentals of programming, circuit production and computer assisted design.

Design 2 - Programming

Analysis of Stepper Motor

Analysis of Stepper Motor

Panel Shifter

Design 2 Reflection

---------------------------------------------------------------------------------------------------------

Design 2 Reflection

---------------------------------------------------------------------------------------------------------

Like many endeavours before it I decided to retire this prototype at roughly the 80% completion mark. This is a habit of mine that garners considerable criticism. To the outside observer it appears indicative of a lack of commitment/follow-through.

In my opinion it is a healthy trend and inherently associated with the learning process.

As knowledge is gained, so follows the shifting of goalposts to higher ambitions. I also consider it an effective method of avoiding sunken cost fallacy;

As knowledge is gained, so follows the shifting of goalposts to higher ambitions. I also consider it an effective method of avoiding sunken cost fallacy;

although admittedly an undeniably painful game of cat and mouse.

Intended Features for Design 2.

I intended for Panel Shifter iteration 2 to have the following features . Instead they will be rolled over into design 3.

I intended for Panel Shifter iteration 2 to have the following features . Instead they will be rolled over into design 3.

Design 3

---------------------------------------------------------------------------------------------------------

Design 3 Feature Summary

---------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------

The new de

internal IC. use multiple or a4988 drivers. W homing sensor multiple IC preferable

add homing sensors

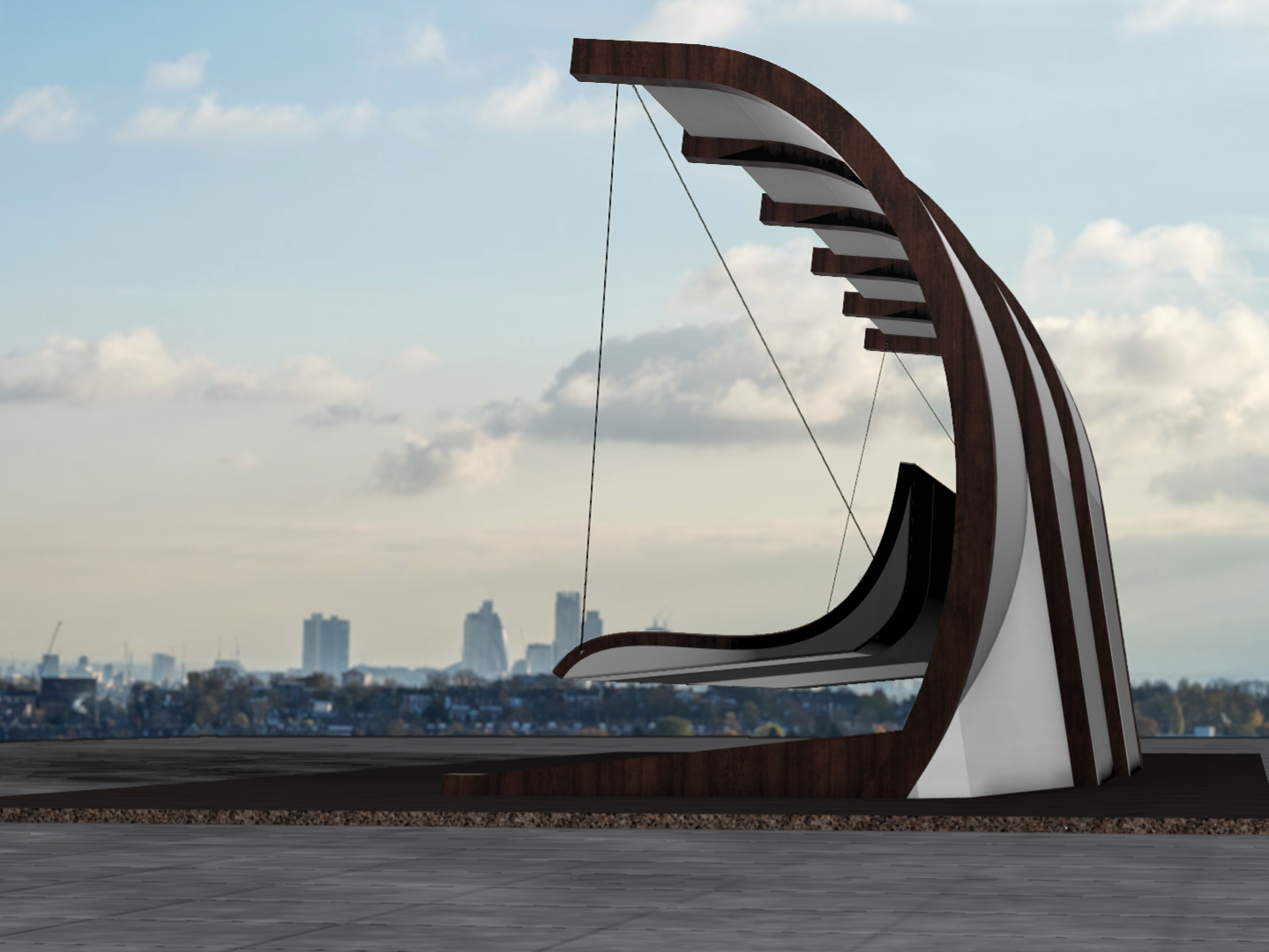

Redesign: Use laser cutter

> Ease of assembly + production quality

> Appearance

> Single base component

Other Proposed Features

---------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------

Bluetooth: phone control

motion detecting

motion detecting